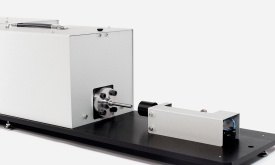

Model 2400 High-Pressure Filling System

The Tridak® Model 2400 high-pressure filling system accurately fills packages with extremely high-viscosity materials such as dental composites and restoratives. Due to “fillers”, composition, and tackiness, these materials can be difficult to dispense and can clog typical filling machines.

The system is semi-automated and bench-top mounted. It consists of the base system and a refillable cartridge/piston assembly that holds bulk material, allowing it to be prepared off-line and permitting the user to conveniently store it for future use.

Tridak fabricates nozzles that precisely match the packages being filled.

Model 2400 High-Pressure Filling System

The Model 2400 High-Pressure Filling System accurately fills packages with extremely high-viscosity materials such as dental composites and restoratives. Due to their high content of “filler”, these materials can be hard to dispense and can clog typical filling machines. The Model 2400 system uses a convection oven to lower the viscosity of the material and then routes it through the system and into the containers using high hydraulic pressure.

Features

Features

- Dispenses extremely high-viscosity, filled materials

- Solid-state sensing system controls the amount of fill

- Includes a forced convection oven to lower material viscosity when needed

- Fills single syringes and compules

- Removable cartridge assembly allows materials to be prepared off-line and permits easy storage of materials for future use

- Quick, convenient changeover of material

- Stainless steel medical version is available

- Other customized versions available – details upon request

Resources

Resources

Infographics

Product Bulletins

User Manuals

System Specifications

Looking for additional technical specifications? Check out our Resource Library or talk with our technical experts.

Get in touch| Property | Specifications |

|---|---|

| Part Number: | T10095 – Model 2400 High-Pressure Filling System |

| Reservoir Size: | 900 mL |

| Required Electrical Power: | 110 VAC, 50/60 Hz |

| Required Air: | Clean, dry, non-lubricated air operating pressure of 60-90 psi [4-6 bar] |

| Dimensions (W x H x L): | 18 in x 11.125 in x 56.75 in (45.72 cm x 28.26 cm x 144.15 cm) |

| Compatible Viscosity Range: | Non-flowing pastes only |

Looking for additional technical specifications? Check out our Resource Library or talk with our technical experts.

Get in touch

Contact Us

Interested in learning more about Tridak solutions or have questions?

Get in touch with us today, we want to hear from you.