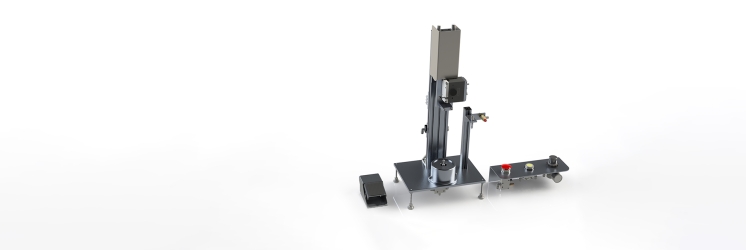

Model 1060 Syringe & Cartridge Filling System

The Tridak® Model 1060 filling system is designed to fill syringes and cartridges, one at a time, quickly and accurately from a material reservoir. The system is manually loaded and unloaded, making it ideal for low-volume production or as an alternative to filling syringes manually. A variety of tooling nozzles are available, making the system compatible with a range of syringe/cartridge designs. It can accommodate syringes or cartridges from 30-900 ml in size and fluids having a viscosity of 1-60,000 cP. It utilizes a Model 830 disposable fluid path valve to make material changeover fast and easy while minimizing cross-contamination. This valve also features an adjustable suck-back for accurate, clean cut-off for stringy or tacky materials.

Features

Features

- Utilizes disposable fluid path valve technology which minimizes cross-contamination, clean-up, and downtime during product changeover

- Dispensing valve features adjustable suck-back for a clean dispense of stringy and tacky materials

- An adjustable pneumatic stop assures accurate fills

- Foot switch for hands-free fill cycle activation

- System fills 30-900 mL syringes or cartridges with pre-inserted pistons; tooling nozzles are available for a variety of syringe/cartridge designs

- Includes a control panel that incorporates an emergency stop switch, material prime switch, and a cylinder pressure regulator

- Available with clear or opaque (black) fluid tubing

Resources

Resources

Product Bulletins

User Manuals

Infographics

System Specifications

Looking for additional technical specifications? Check out our Resource Library or talk with our technical experts.

Get in touch| Property | Specifications |

|---|---|

| Part Number: | T18626 – Model 1060 Filling System |

| Input Air Pressure: | Input Air Pressure80 psi (4.1 bar) min / 100 psi (6.9 bar) max |

| Dimensions (L x W x H): | 8.5 in x 12 in x 28.5 in (21.6 cm x 30.48 cm x 72.40 cm) |

| Viscosity Range: | 1 – 60,000 cP (or much higher depending on type of reservoir used) |

Looking for additional technical specifications? Check out our Resource Library or talk with our technical experts.

Get in touch%20Disposable%20Syringe%20Barrels.png)

.png)

.png)

Contact Us

Interested in learning more about Tridak solutions or have questions?

Get in touch with us today, we want to hear from you.